MATERIAL PASSPORTS

Material Passporting and Circular Asset Management

Urban Mining

The built environment is a vast deposit of valuable resources. Each year it claims over half of all materials extracted from the Earth’s surface.

Yet we waste almost everything that goes into these building stocks. 98% of construction materials are destined to be degraded into low-value end-of-life uses.

What if, instead of generating waste, we could enable our buildings to be an abundant stock of resources? Urban mines of valuable materials whose value could be maintained for as long as possible?

Industry 4.0 now allows us to do so. By digitally enabling our buildings to be Material Banks we can unlock their financial and circularity potential.

Material Passports

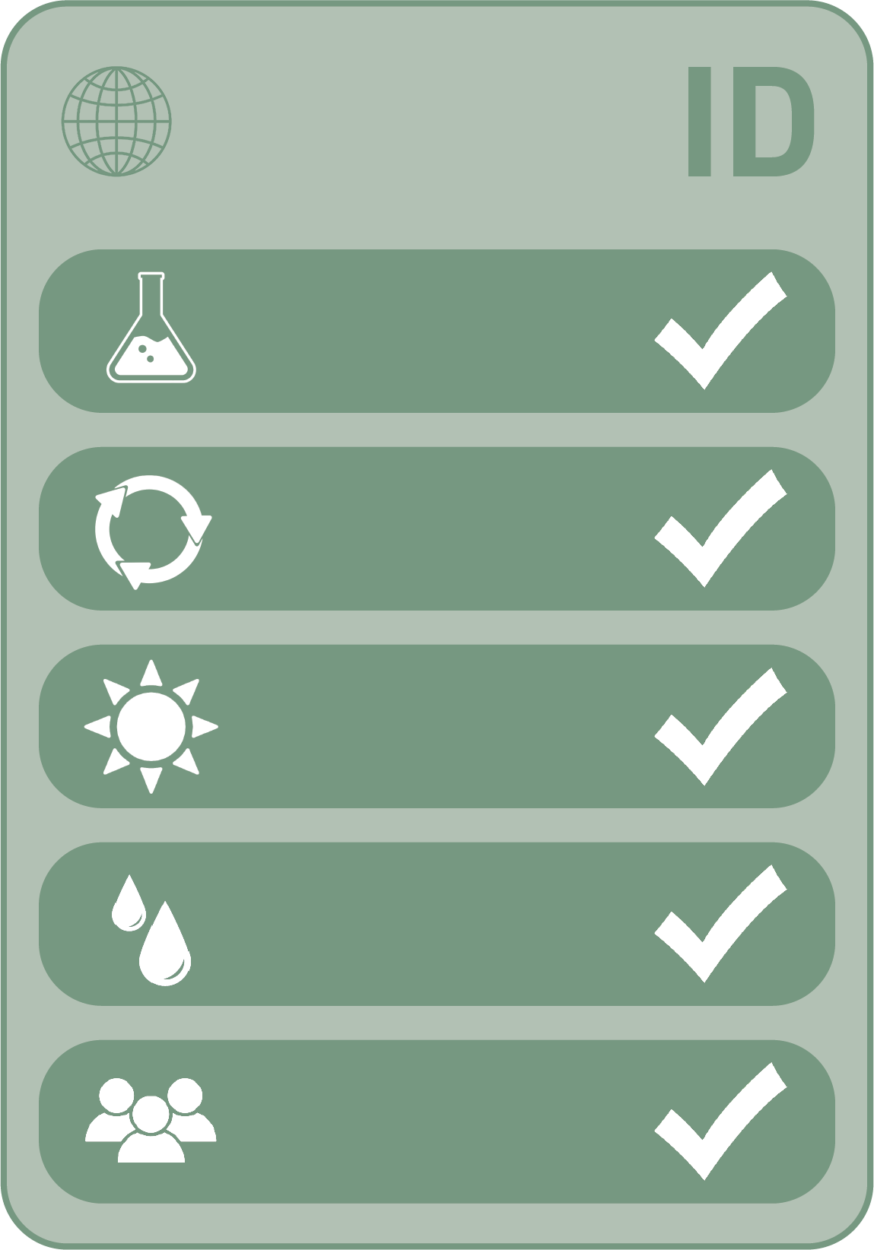

Material Passports can be seen as digital ID cards for materials, which record key information such as carbon footprint, circularity, material health and residual value, to prepare them for end-of-life.

Material Passports are required to accurately digitise our building stock.

“We propose that from 2025 onwards, every construction project should have materials passports as a key deliverable.” – ORMS Policy Paper

Carbon Footprint

Circularity

Related Documentation

Composition & Material Health

Level of Dissasembly

Next Lives

Energy & Water Consumption

Recording the circularity potential of materials as built is essential to enable reuse and decarbonisation.

The industry recognises them as a key innovation allowing for traceability and transparency of material flows.

They provide a value add at every phase of a building’s lifecycle, from the initial design to the construction and in-use phase, all the way to deconstruction.

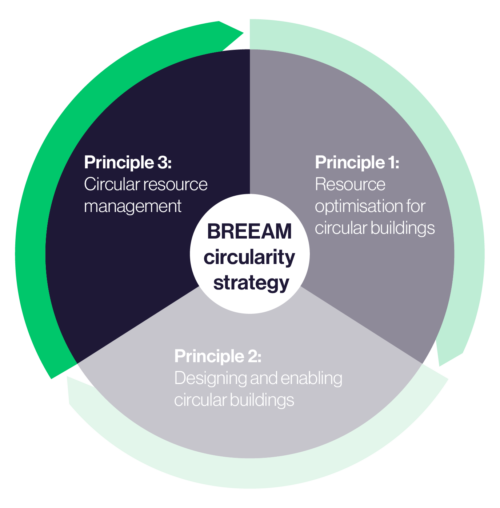

“…focus should be on the provision of digital information on construction products (i.e., material passports), giving easy access to material and component data facilitating reuse and recycling as well as socio-environmental metrics and financial residual values.”

– BREEAM principles for circular buildings

Original Image URL: https://www.bre.group/breeam-circularity-principles

Material Passports are gaining increasing acceptance as a fundamental tool in promoting both circular economy and decarbonization and are seen as an innovative mark of high quality green development.

The Mayor of London’s London Plan describes them as a key enabler that can support the delivery of Pioneering Circular Economy Statements.

As both policy and the market increasingly converges on the need for Material Passports to drive circular economy forward, talk to us now about how you and your clients can be at the forefront of the latest ClimateTech innovations in this space.

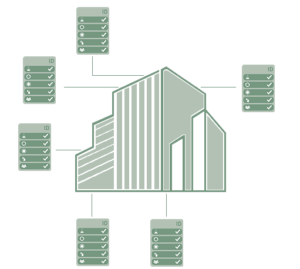

Digital Material Banks

A dynamic Digital Material Bank will be made up from all the Material Passports associated to your building or project. Material Banks are built with disassembly and end-of-life in mind, to maximise resource recovery during refurbishment or deconstruction.

The Digital Material Bank will give you and your clients an overview of the building as built, which can be easily updated during renovations and fit-outs.

It makes decarbonising your building further throughout its lifecycle possible, by specifying low-carbon, circular and reused materials.

Why Building Data is the New Oil

The race to unlock competitive advantage and risk proof assets amid climate change has begun. A futureproofed building needs to be able to change and adapt to the needs of its users and maintain its value in an increasingly exacting regulatory environment.

As investors, governments and clients respond to our changing planet, asset owners now face the need to understand the material flows of their projects: What is going in, what is present, what is coming out. Poor quality or badly suited materials will only emerge as waste, leading to cost, regulatory penalties, reputation damage and missed opportunity.

Enabling a circular building provides a differentiator which will make your project or building stand out. Quickly repurpose assets and reuse components to make adaptable, flexible and longer lasting structures.

Whether you are a designer, contractor, consultant or asset owner, we can help. Enable your team to deliver their function in the circular built environment and guarantee a pioneering project. Doing nothing is no longer an option, the question is, how are you securing your asset against the test of time?

Reduce cost through Reclamation & reuse

- Digitally enable your buildings to be rich resource mines.

- Reduce the need for expensive virgin materials in new projects or refurbishements.

- Reduce embodied carbon and demolition costs.

- Ensure that your materials can be removed with minimal effort, contamination and without loss of quality.

- Plug into a materials exchange, allowing waste and excess materials to become revenue streams.

Reduce risk through Reuse

- Comply with government guidance and regulation requiring circular and embodied carbon strategies.

- Design adaptable buildings with increased flexibility in use options.

- Provide complete, auditable carbon impact data with full transparency on your materials.

- Keep valuable materials in use for as long as possible by making sure they are accessible and functional.

- Guard against supply chain shocks by reusing materials from other assets in your portfolio, with a complete data trail.

Increase returns through Renewal

- Build pioneering developments by achieving SI 7 London Plan targets.

- Demonstrate ESG compliance for finance and investment.

- End Greenwashing with reliable, auditable and traceable data sets.

- Monitor and phase out hazardous or toxic materials and processes. Substitute them with non toxic or biophilic products.

- Increase yields by developing healthy, low carbon and flexible buildings that are more attractive, viable assets for occupiers.

Stakeholders

1.

Product Manufacturer

Provide specific product information to generate Material Passports.

2.

Architect

Specify materials with associated Material Passports (to calculate key environmental & financial indicators)

3.

Contractor

Update the Material Passports with as build details: installation, demountability.

4.

Asset Owner

Update with maintenance and in-use information. Circular Management of their assets resulting in financial benefits.

5.

Demolition Contractor

Record material flows in a pre-demolition audit to enable reuse.

6.

End-of-life Transformation Actors

Necessary transformations to prepare materials for their next life.

The Most Advanced

Circularity Tool

on the Market

As our technology partner for implementing Material Passports, we have worked together in both the UK and Europe in developing cutting-edge technology and experienced on-site management.

They are a leading Material Passport platform that allows you to track the full cycle of your building from design to the construction and in-use phases all the way through deconstruction. To ensure the longevity of materials, the platform facilitates the reuse at end-of-life through an exchange marketplace.

Their philosophy is closely linked to Cradle-to-Cradle, following the key principle that everything is a resource and that the notion of waste does not exist.

Following this path of creating a positive impact, they created the largest reuse hub in France.

Combining Material Passports with a reuse marketplace, allows for transparency of information and increased trust between actors.

The myUpcyclea software was used by Multiplex on their Nine Elms project to digitise part of the fit-out packages

CASE STUDIEs

Reuse of Demolition Waste with Domofrance

"At Domofrance, we manage a housing stock of 40,000 homes and renovate...

Multiplex Successfully Trials Material Passports

At Maconda Solutions, we are all about driving practical solutions and we...